2025.12.15

2025.12.15

ข่าวอุตสาหกรรม

ข่าวอุตสาหกรรม

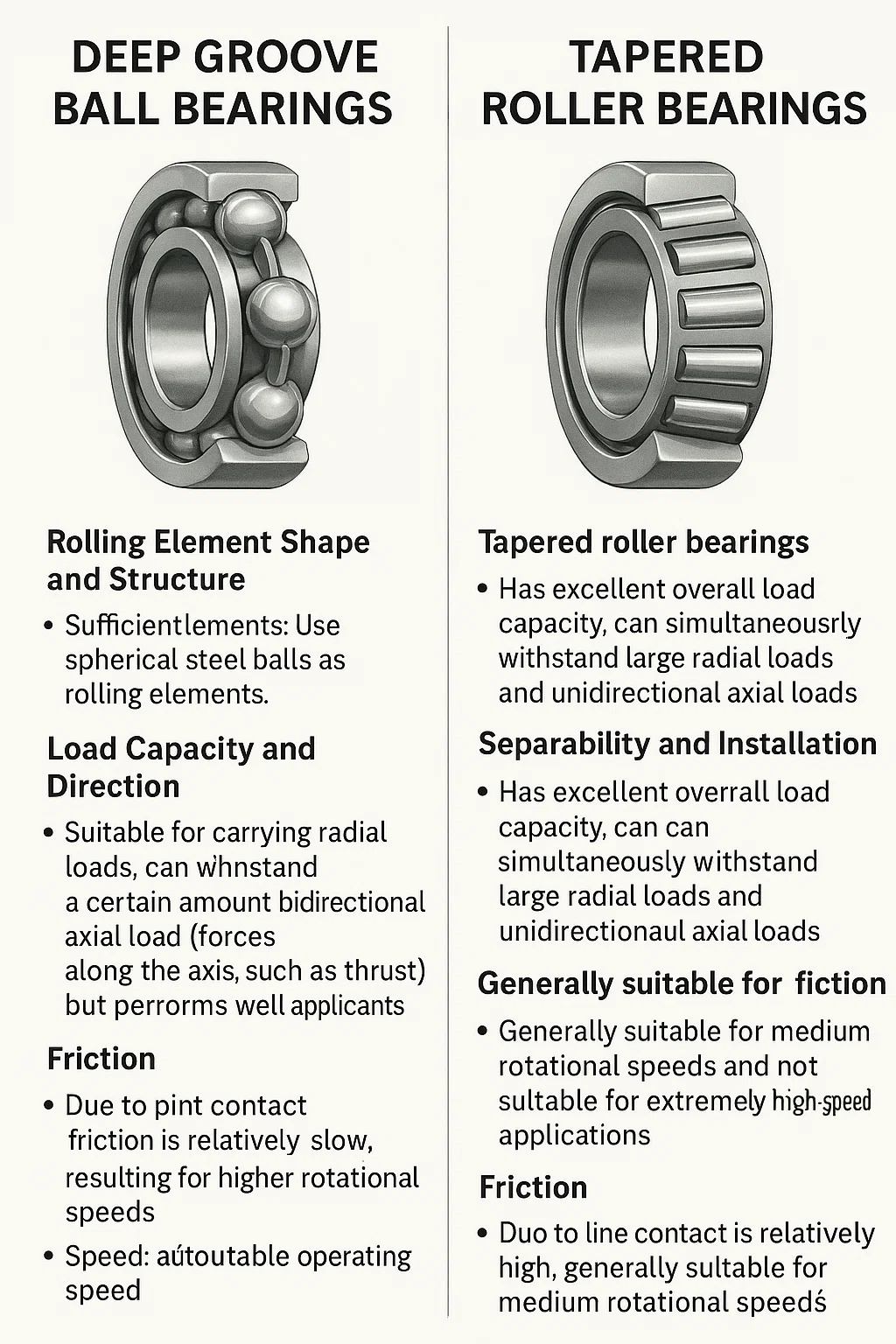

Bearing Type Comparison: Deep Groove Ball Bearings vs. Tapered Roller Bearings

Deep groove ball bearings and tapered roller bearings are two very common types of bearings, and they have significant differences in structure and application.

• Deep Groove Ball Bearings

Rolling elements: Use spherical steel balls as rolling elements.

Structural characteristics: The rolling elements (steel balls) run in deep circular raceways between the inner and outer rings. This design results in a small contact area during operation.

• Tapered Roller Bearings

Rolling elements: Use truncated cones (tapered rollers) as rolling elements.

Structural characteristics: The raceways (inner and outer rings) and rollers all have a taper, and all their tapered surfaces intersect at a common point. This structure provides a larger contact area.

• Deep Groove Ball Bearings

Main load capacity: Suitable for carrying radial loads (forces perpendicular to the axis, such as supporting the weight of a rotating object).

Secondary load capacity: Can also withstand a certain amount of bidirectional axial load (forces along the axis, such as thrust), but the axial load capacity is relatively limited.

Characteristics: Performs well in applications with purely radial loads and high-speed rotation.

• Tapered Roller Bearings

Main load capacity: Has excellent overall load capacity and can simultaneously withstand large radial loads and unidirectional axial loads.

Characteristics: Very suitable for applications with large impact forces or where precise control of axial position is required, such as in automotive wheel hubs.

• Deep Groove Ball Bearings

Structure: Usually a non-separable unit (except for special types), meaning the inner ring, outer ring, and rolling elements are typically installed as a single unit.

Installation: Installation is relatively simple and quick. • Tapered Roller Bearings

Structure: These are separable bearings, typically consisting of an inner ring assembly with rollers and cage (tapered assembly) and an outer ring (cup assembly) that can be separated.

Installation: This separable structure facilitates installation and removal, but during installation, it is usually necessary to adjust the clearance (or preload) between the two halves of the bearing to ensure correct operation.

• Deep Groove Ball Bearings

Friction: Due to point contact, the friction is relatively low, resulting in low heat generation.

Speed: Suitable for stable operation at higher rotational speeds.

• Tapered Roller Bearings

Friction: Due to the line contact between the rollers and raceways, and the sliding friction between the roller end faces and the inner ring flange, the friction is relatively high.

Speed: Generally suitable for medium rotational speeds and not suitable for extremely high-speed applications.

• Deep Groove Ball Bearings

Rigidity: Relatively low.

• Tapered Roller Bearings

Rigidity: Due to the characteristics of line contact and precise preload adjustment, it can provide very high rigidity, making the shaft support more robust.